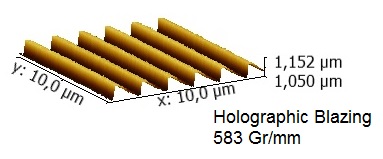

A second method uses holographic exposure to generate blazed profiles in photoresist and was first proposed in a standing wave setup by Sheridon (Appl. Phys. Lett. 12,v 316,(1968)). DIOS uses an extension of this method - the Inclined Nodal Plane Holography.

Ion Beam Blazing and Holographic Blazing have different advantages and disadvantages. Compared to mechanical ruling all holographic methods give a better stray light. And all holographic methods can be applied not only for plane, but also for surfaces with significant deviation from plane surfaces.

Disadvantage of Ion Beam Blazing is that it is restricted to blaze angles > 5°. Holographic Blazing is restricted to transparent materials and has much more critical process steps than any other method of grating manufacturing.

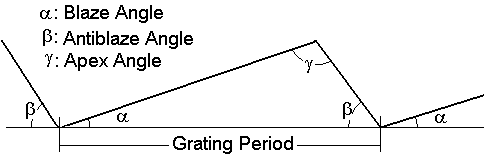

The defining parameters for a blaze profile is the blaze angle and the anti blaze angle. The blaze angle determines the wavelength position of the efficiency peak. To a lower extent, the anti blaze angle can influnece the efficiency.

For blaze angles of less than 10° the anti blaze angle is very small, as well, so that the apex angle is much larger than 90°

Holographic Blazing 583 Gr/mm, Blaze Angle 2.6°