The groove pattern of a grating with a variable groove density has imaging properties like an optical surface. The grooves are not equidistant but varying over the grating area. In most cases, the variation of the groove density along the direction of dispersion is given by a polynomial function. For application for synchrotron radiation, these gratings are often designated as VLS grating (Variable Line Spacing Gratings).

This technique is applicable for laminar gratings as well as for gratings generated by holographic blazing.

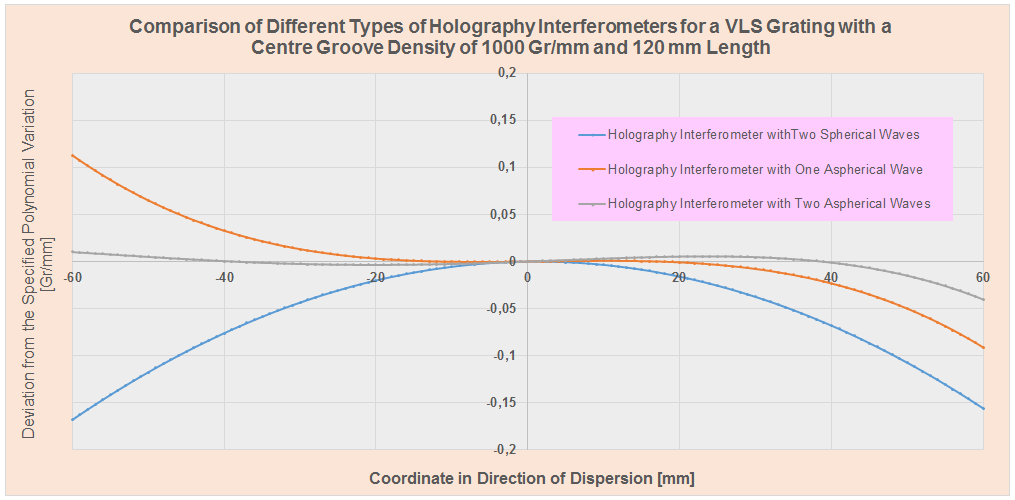

VLS gratings can be manufactured by a holography interferometer with a combination of spherical and aspherical waves.

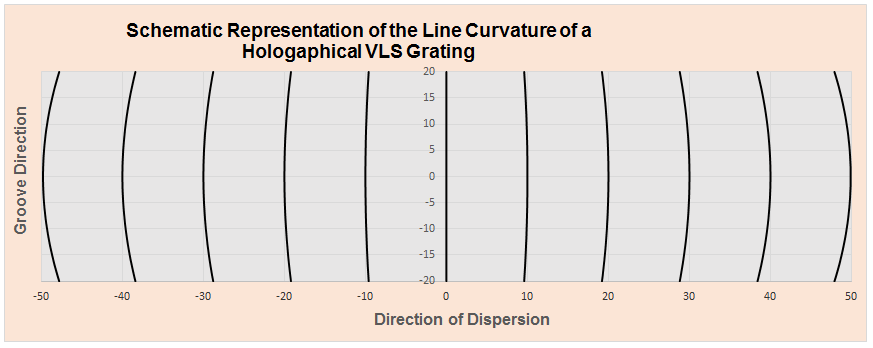

A general effect of the recording of VLS gratings by a holography interferometer is the line curvature. The line curvature in the centre can be set to zero by design (Radius of the groove is infinite).

Not all types of polynomial variation can be generated with this type of holography interferometer. The combination of a spherical and an aspherical wave or two aspherical waves is necessary, to achieve a good approximation of the specified polynomial variation. Holography interferometer with aspherical waves may have a line curvature which is up to a factor of 100 higher than for the basic solution with two spherical waves.